We have been spending extra time on the Federal Register to keep a close eye on the policy put through the federal government, and this one caught my attention. It’s not often that we pay regard to anything other than environmental policy, but this falls in that category for one reason, it’s hypocritical. It’s impressive to see this policy being put through while a significant energy shift is taking place right now. With major utility companies switching to solar by 2030 and environmental groups pushing to destroy nuclear energy, this policy is wholly contradictory to the narcissistic ecological concerns of the Biden administration.

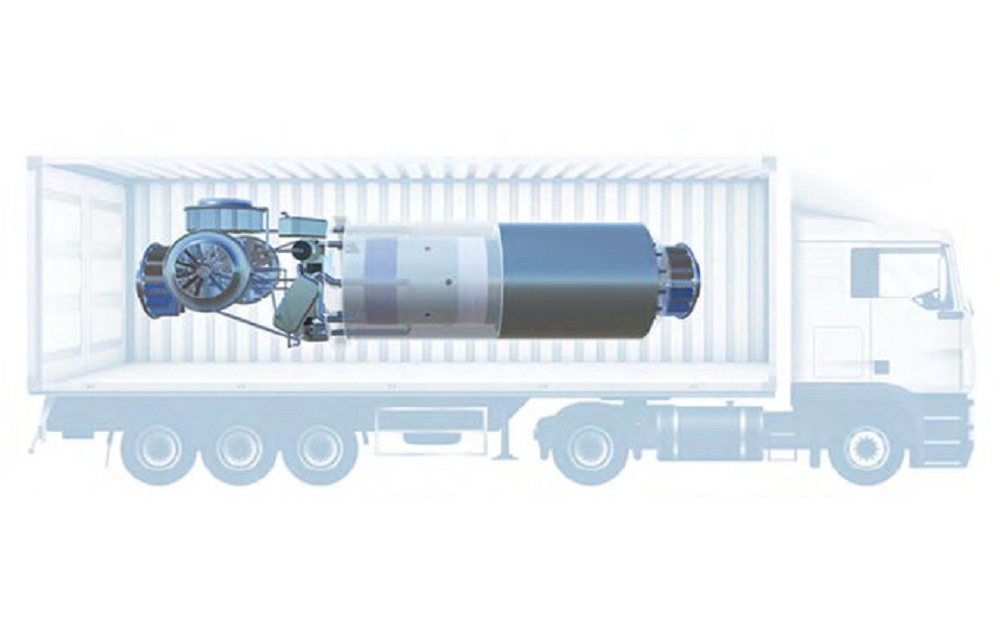

The Department of Defence is currently asking for public comment concerning the testing of small, portable nuclear reactors that will be used to provide 1-5 megawatts of electricity for use in the United States Armed Forces Remote Operating Bases. The testing will take place at the Idaho National Laboratory Testing Facility and will last a total of 5 years. They intend to test if they safely assemble, run, disassemble, and store the gas-cooled nuclear microreactor.

You can see the project website to learn more about this proposal.

According to The Office of Nuclear Energy, microreactors can produce up to 20 megawatts of thermal energy used for heating, producing electricity, desalinating saltwater, and hydrogen fuel production. On their website, the Department of Energy claims to “support various advanced reactor designs including gas, liquid metal, molten salt, and heat pipe cooled concepts” and lumps microreactors in with renewable energy claiming a seamless integration.

You can find all the documents concerning this project in the Federal Register or on the project website, including a detailed description of the proposed actions. It’s an interesting read. Have a look!

[jsoncontentimporter url=”https://www.federalregister.gov/api/v1/documents/2021-20546?publication_date=2021-09-24″ debugmode=”0″ basenode=””object””]

{title}

{dates}

Document Number: {document_number}

{action}

{abstract}

Proposed Action

The Proposed Action in the Draft EIS consists of constructing and demonstrating a prototype mobile microreactor at the INL site that would be capable of producing 1 to 5 MWe. The mobile microreactor is expected to be a small, advanced gas-cooled reactor using high-assay low-enriched uranium (HALEU) tristructural isotropic (TRISO) fuel. TRISO fuel is encapsulated and has been demonstrated to be capable of withstanding temperatures up to 1,800 degrees Celsius (°C), allowing for a reactor design that relies primarily on simple passive features and inherent physics to ensure safety.

Mobile microreactor fuel loading, final assembly, and demonstration would be performed at the INL Site using DOE technical expertise and facilities at the Materials and Fuels Complex (MFC) and Critical Infrastructure Test Range Complex (CITRC). Reactor fuel would be produced from DOE stockpiles of highly enriched uranium (HEU) located at DOE’s Y-12 plant in Oak Ridge, Tennessee that would be converted to an oxide form at the Nuclear Fuel Services (a subsidiary of BWXT) facility in Erwin, Tennessee, and down blended to HALEU and fabricated into TRISO fuel at the BWXT facility in Lynchburg, Virginia.

Demonstration Activities at the INL Site

The Project Pele activities to be performed at the CITRC and MFC facilities on the INL Site, would involve demonstration that the proposed mobile microreactor could produce reliable electric power onto an electrical grid that is separate from the public utility grid and that the mobile microreactor can be safely disassembled and moved. At the end of an approximately 3-year demonstration, current plans are that the mobile microreactor would be shut down and placed into a safe storage mode at the INL Site.

The mobile microreactor would arrive at the INL Site for installation at MFC without reactor fuel. The possible locations to perform the fueling of the mobile microreactor are either the Transient Reactor Test Facility (TREAT) or the Hot Fuel Examination Facility (HFEF). Final assembly of the mobile microreactor modules would be performed at the site of the initial startup testing. The initial startup testing of the mobile microreactor could be performed at the Demonstration of Operation Microreactor Experiments (DOME) facilities in the Experimental Breeder Reactor II (EBR II) building.

Improvements to the DOME are planned in support of other programs at the INL Site. These improvements to the DOME, while not a part of Project Pele, are necessary for the DOME to be capable of supporting the initial startup testing phase of the mobile microreactor demonstration. Should these improvements not be made in time to support Project Pele schedule, final assembly and startup testing would be performed at CITRC. At either location, final assembly entails connecting the mobile microreactor modules. The modules within the CONEX containers would be attached via cables, conduit, and pipes that would have been transported with the mobile microreactor to the INL Site. During this phase of the demonstration, the mobile microreactor would not be connected to an electrical distribution grid. Startup testing would be performed to verify that the mobile microreactor would perform as designed. The startup and initial testing phase is anticipated to take 6 months to complete.

Disassembly and transport would occur between the startup testing phase and the operational testing phase at CITRC regardless of where startup testing would be performed. In either case, the disassembly and transport would provide proof-of-concept of the mobility of the mobile microreactor. The mobile microreactor would be disassembled at the startup testing site with minimal temporary laydown requirements. The mobile microreactor would be placed in a safe shutdown mode in which decay heat would be removed via the passive heat removal systems. This phase is anticipated to take around 5 weeks to complete.

Mobile Microreactor Activities at CITRC

CITRC is part of the INL’s 61-mile 138-kilovolt (kV) power loop electric test bed and supports critical infrastructure research and testing. CITRC includes a configurable and controllable substation and a 13.8-kV distribution network. Four test pads are located at CITRC within the CITRC distribution grid. Some testing connects multiple test pads using the CITRC microgrid distribution infrastructure. These graveled/paved test pads furnish areas to place test equipment ( e.g., transformers, circuit breakers, switches). Test pads also serve as parking areas for personnel performing setup and testing. Preparation of the CITRC site would be performed over the course of up to 6 months prior to the arrival of the mobile microreactor at the site. Preparation would involve construction of a 200-foot by 200-foot concrete pad about 8 inches thick to create a level surface for the CONEX containers.

Upon arrival at CITRC test pad area B, C, or D, the mobile microreactor would be offloaded from the transports to the new concrete pad at the test pad area and the mobile microreactor modules reconnected. The temporary shielding, consisting of concrete T-walls, steel-reinforced concrete roof panels, concrete wall blocks, steel bladders for water shielding, and HESCO® bags, would be installed. The completed shielding structure would be about 5,000 square feet and up to 30 feet tall around the microreactor module. A limited version of the startup tests performed at DOME (or CITRC) would be performed to verify that no modules were damaged during transport.

At CITRC, the mobile microreactor system would be connected to the CITRC microgrid which is separate and distinct from the INL/commercially supplied electrical grid. Diesel generators and load banks would be attached to the microgrid. The generators and load banks would apply realistic loads and supplies to the microgrid to test the mobile microreactor in a realistic setting. Additional pads would be used to house the load banks and diesel generators to simulate a microgrid (electrical power loads for the mobile microreactor) during testing.

At-power testing, performed according to test procedures yet to be developed, would verify the ability of the mobile microreactor to operate at its rated power level for an extended period under normal, off-normal (but expected), and upset (not expected but anticipated) conditions. Transient tests performed would demonstrate mobile microreactor features, not push it to damage conditions. Transient testing would demonstrate upset conditions that would last at most a couple of days but more likely hours. In addition, the CITRC site would require a mobile office trailer that could contain a restroom, potable water, donning/doffing facilities, equipment storage, charging stations, etc. The mobile microreactor operations phase at CITRC is anticipated to take around 2.5 years to complete. Start Printed Page 53041

Temporary Storage

After operational testing, the mobile microreactor would be disassembled and placed in temporary storage, awaiting eventual disposition. There are two options for temporary storage of the mobile microreactor system (within their CONEX containers) at the INL Site: the RSWF receiving area (MFC-771) and ORSA (MFC-797). A reinforced concrete pad would be constructed at either of the temporary storage locations, and minor upgrades in fencing and instrumentation would be required if stored at ORSA.

Post-Irradiation Examination and Disposition

After the mobile microreactor’s useful life is complete and after a period of temporary storage, all of the materials would be disposed. The mobile microreactor components would be disposed of through the appropriate waste streams. It is anticipated that the mobile microreactor would be deconstructed and parts and/or fuel removed to aggregate like-class wastes. After deconstruction, irradiated materials would be safely stored with other similar DOE-irradiated materials and experiments at MFC, most likely in the HFEF or the RSWF. Ultimate disposal of the irradiated materials that have been declared waste would occur along with similar DOE-owned irradiated materials and experiments currently at MFC.

[/jsoncontentimporter]